The scenario is this: Say that to avoid noise, you've setup the compressor in your garage and run an air line to your hobby room. In some cases someone will want to use air tools in the garage at the same time someone else is airbrushing. In other cases, maybe two people want to be able to airbrush at the same time.

The only drawback to these scenarios is that hobby compressors won't be able to output enough pressure in most cases. In order to do these things, you'll probably need a larger professional compressor that can handle at least 100 psi out, preferably more like 150 psi.

- Garage

As I mentioned above, we're assuming the compressor is setup in the garage.

- The first thing in line is a manifold.

- This splits the air between the garage and the hobby room.

- After the manifold, both directions gets a valve.

- It's always a good idea to give yourself some more control over the line.

- If you want to use air powered tools in the garage, put a regulator after the valve.

- This sets the pressure the tools need.

- Finally, the tools themselves.

You may also want to put a water / dust trap on the compressor, right before the first manifold. (Since garages can get dusty)

- Hobby Room

From the garage, run a line to your hobby room.

Keep in mind that you can lose pressure over longer distances, so you might need to turn the pressure up a little bit to compensate for this.

- Single Airbrush Setups

The first and cheapest method is to connect the airbrush directly to the line from the garage. If nobody plans on using the compressor for anything else and won't be fiddling with it when you're not using it, that's fine.

For safety's sake, I recommend a valve to cut your airbrush off from the line, just incase someone uses the compressor and turns the line above the airbrush's max pressure rating. (damaging it)

- Connect a manifold to the line from the garage.

- This allows you to connect an gauge.

- The gauge lets you see what pressure the compressor is set at. (including if there's loss from distance)

- To the other side of the manifold, connect a safety valve.

- Cuts the airbrush off from the main line, protecting it from the compressor being turned up.

- Then connect the airbrush to the valve.

This is less equipment to deal with, and more organized. The downside is that regulators like this tend to be somewhat expensive.

- Connect the regulator to the line from the garage.

- Connect the airbrush to the output from the regulator.

- The regulator displays the pressure from the garage.

- It also displays the output as you adjust the output pressure.

- Dual Airbrush Math

Sometimes multiple people will want to airbrush at the same time. This requires the use of multiple regulators because you have to increase the pressure from the compressor so it can handle both airbrushes being used at once.

If:

Airbrush A is being used at 30 psi.

Airbrush B is being used at 45 psi.

Then the total psi on the line should be AT LEAST 75 psi.

That provides enough pressure for both to operate at the same time.

HOWEVER, airbrushes usually shouldn't be operated at 75 psi, meaning you can damage your airbrush if there isn't an extra regulator to step the pressure down.

- Dual Airbrush Setups

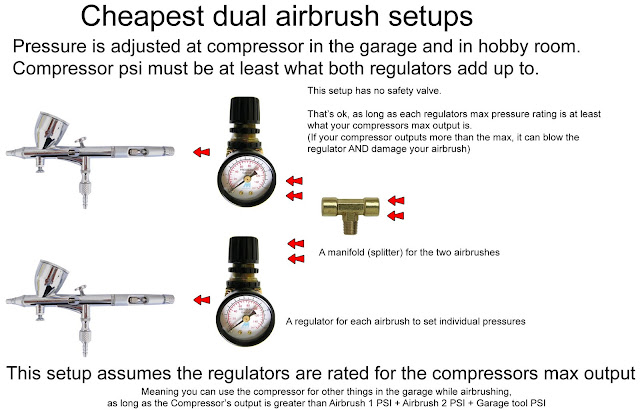

The cheapest way to split your line is to put a splitter on the line followed by two regulators. Remember, anything you connect to an air line should be able to handle the maximum that your compressor can handle - that way if the compressor is turned up real high and you don't realize it, you don't damage your equipment.

- A manifold splits the line from the garage

- It feeds two regulators.

- Each regulator allows each airbrusher to use a different pressure.

- An airbrush connects to each regulator.

Say you have a high end compressor in the garage, and buy a couple regulators with a maximum pressure rating only good enough to feed the airbrushes to save money. You don't want to blow the regulators if the compressor is turned up too high - so in this example, we use a safety valve that allows you to partially open it or close it off when it's not in use.

I'm not a fan of this setup, because ideally you'll only use equipment rated for the line, in order to prevent damage to your airbrush and other line equipment.

- A manifold connects to the line from the garage.

- It splits to a gauge to monitor the pressure on the line from the garage.

- It also splits to a safety valve.

- This safety valve feeds a 3-way manifold.

- One split feeds a gauge to display the pressure after the valve.

- This allows you to monitor the pressure on the line if you only open the safety valve partially.

- The other two each feed a regulator.

- An airbrush connects to each regulator.

The cleanest way to split an air line, is to use a proper higher end regulator. (But again, these can be expensive.)

- Place a regulator on the line from the garage.

- These regulators tend to be higher end and handle higher pressures from the compressor.

- Followed by a manifold to split the line.

- The split goes to two smaller regulators.

- And an airbrush connects to each regulator.

Comments are disabled due to the INSANE amount of spam this post attracts. Who knew air compressor companies were so spammy?

Take a look at the Wargaming Tradecraft Techniques Page for links to the entire Airbrushing series and other tips, tutorials and information.

Take a look at the Wargaming Tradecraft Techniques Page for links to the entire Airbrushing series and other tips, tutorials and information.

No comments :

New comments are not allowed.